Fastener Glossary

Your guide to key fastener terms & technology

Nylok moves quick to bring you the latest and greatest technological advancements in fasteners. This page is designed to help you stay current with all the key terms and technology definitions. It’s just another way Nylok has you covered!

TORQUE DEFINITIONS

Installation Torque

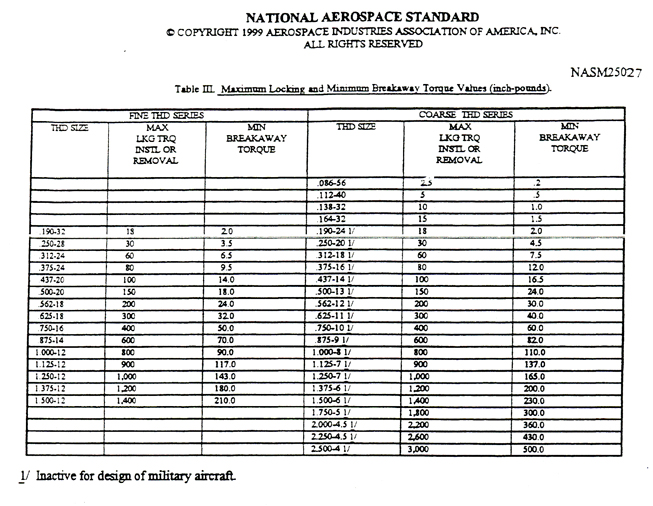

The highest value of prevailing torque produced the first time the self-locking fastener is being installed. This is taken during the first five revolutions after engaging the locking element and before seating.

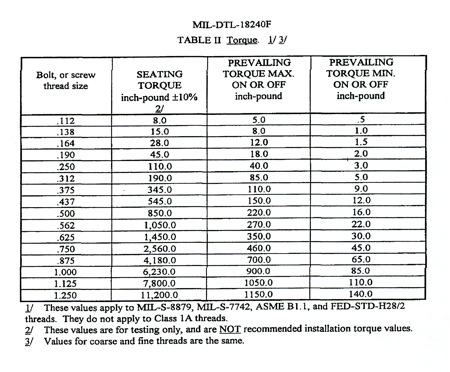

Seating Torque [Loading Torque, Tightening Torque]

A value of torque typically measured in “inch-pounds” applied to a fastener to induce a compressive load under the head bearing surface that results in creating an axial load (pre-load).

Breakloose Torque

The amount of torque required to put into reverse rotation a fastener that is in the seated, clamped or tightened position. The torque is due to clamp load and not related to prevailing torque.

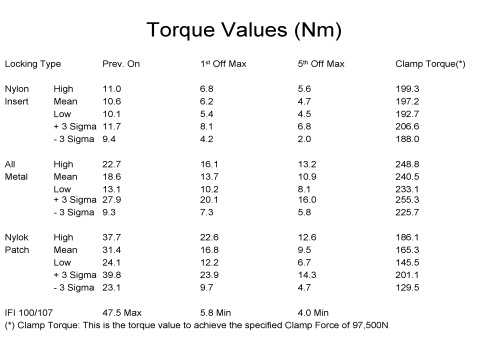

Breakaway Torque [Static Torque, Off Torque, Removal Torque]

The torque required to begin reverse rotation in a fastener that has not been seated. This will change with reuse—they are referred to as the “1st Off, 5th Off” torque. This torque is due to the locking element only and is considered a critical performance characteristic of a locking component.

Prevailing “Off” Torque

The torque readings taken as the part is backed off during the first 360° of rotation. This is after clamp load has been reduced to zero.

Prevailing Torque [Running Torque]

An average measure of frictional resistance produced during rotation in either the installation or removal cycle. It is independent of clamp load. This is unique to self-locking fasteners and components.

INSTALLATION TORQUE RECOMMENDATIONS

Light Torque

1/3 of initial installation value i.e. MIL spec.

Standard Torque

2/3 of initial installation value i.e. MIL spec., plus requirement of removals and clamp load. Example: If the maximum initial installation torque is 100 in. lbs, it would be two-thirds at 66 in. lbs with a potential variance ranging between 60-75 in. lbs.

Heavy Torque

3/3 of initial installation value i.e. MIL spec., plus requirement of removals and clamp load.

Hand Torque

2 to 5 in. lbs initial installation only. Removal torque for reference only. Parts to be assembled/dissembled by hand/fingers.