NyShield®

Galvanic Corrosion Protection

EXPANDING OPTIONS FOR FASTENING DISSIMILAR METALS

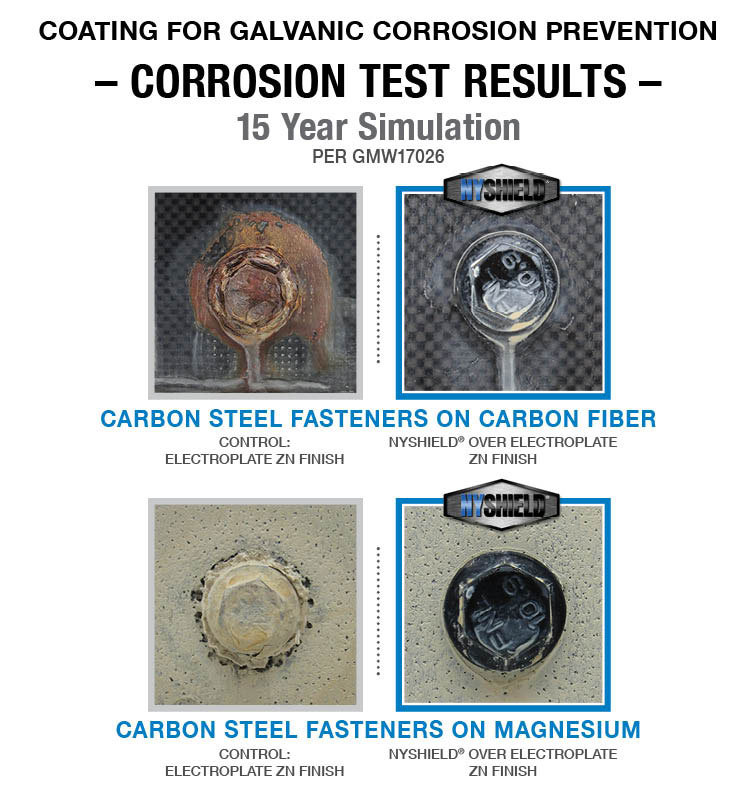

NYSHIELD® is effective in preventing galvanic corrosion between steel fasteners and the most extreme lightweight materials – which include both magnesium and carbon fiber.

NYSHIELD® is applied uniformly to the steel fastener surfaces that contact dissimilar materials, and shields/protects the least noble material. This product has minimal clamp load loss (compared to control but without NYSHIELD®) while maintaining an exceptional chemical resistance and adheres well to most substrates.

NYSHIELD® protects steel fasteners from galvanic corrosion in high-risk material combinations:

- Carbon Fiber

- Magnesium

- Aluminum

- Chrome Plating

- Others

In response to customer demands, Nylok developed and released a new product (NyShield®) that is effective in preventing galvanic corrosion between steel fasteners and the most extreme lightweight materials (including magnesium and carbon fiber), as well as all metals in-between (aluminum, stainless steel, chromium, etc.). This product allows for the use of steel fasteners for these “at risk” joints instead of turning to much more expensive and less practical alternatives. At this time when these materials are being used to light weight many products this has become a major issue especially in the automotive industry. Also, up to this time there has been very few coatings that can withstand harsh environments as constant exposure to ocean water. Nylok’s breakthrough product NyShield® has been tested and protects to over 1,000 hours of salt spray testing in these extreme environments.

Advantages

- Provides exceptional galvanic corrosion resistance (steel fasteners with lightweight materials)

- Provides general corrosion protection (passes 15 year test without corrosion)

- Coating Uniformity: typical thickness is 50-90 microns

- Does not affect functionality of HEX or TORX drives

- Low clamp load loss at elevated temperatures (125°C)

- Adjustable Coefficient of Friction (typically between 0.10– 0.16)

- Excellent adhesion, toughness and durability

- Exceptional chemical resistance

- US Patent Nos. 9,738,792, and 10,465,077, other patents pending. Also protected under TWI654265, CA2,972,984, MX 374,094, and KR 10-1935043, other patents pending.

Technical Data

- Corrosion Resistance (steel vs. carbon fiber, steel vs. magnesium) is exceptional after 15 year simulation exposure (GMW17026) (See download for results)

- Coefficient of Friction results are adjustable (typical range 0.10 – 0.16) (See download for results)

- Clamp Load Loss Test & Results: Comparable to control bolt without NYSHIELD® (See download for results)

- Tape Adhesion Test: 10 days @ 40°C in 100% RH chamber, cross hatch cut in coating/tape pull: no removal of coating (Per GMW14829) (See download for results)

- Chemical Resistance Tests: • 24 hour soak (engine oil, coolant, transmission fluid, power steering fluid, windshield washer fluid, vehicle cleaning agent, transit coating/protective wax, car shampoo, paintwork cleaning product) • 2 hour soak (E10 fuel, E85 fuel, diesel fuel, Windex, Rain-X, 2-in-1 glass cleaner, remover for transit coating, washer fluid) • 10 minute soak (tar and road oil cleaner, chrome cleaner) • Results: no visual change in coating appearance: no noticeable softening of coating (See download for results)

- Durability: Good corrosion resistance after coated fastener is subjected to drop test

Downloads

NYSHIELD® Product Bulletin

Product Bulletin

NYSHIELD® Product Bulletin

Product Bulletin

Corrosion Chamber Test Carbon Fiber vs NyShield®

Performance Test

Corrosion Chamber Test Carbon Fiber vs NyShield®

Performance Test

Corrosion Chamber Test Mg vs NyShield®

Performance Test

Corrosion Chamber Test Mg vs NyShield®

Performance Test

Clamp Load Loss Test

Performance Test

Clamp Load Loss Test

Performance Test

COF Test

Performance Test

COF Test

Performance Test

Tape Adhesion

Performance Test

Tape Adhesion

Performance Test

Coating Uniformity

Performance Test

Coating Uniformity

Performance Test

Chemical Resistance Test

Performance Test

Chemical Resistance Test

Performance Test

NyShield Finish Study Test

Finish Study Test

NyShield Finish Study Test

Finish Study Test

Nylok’s Complete Testing Capability Guide

White paper

Nylok’s Complete Testing Capability Guide

White paper

Videos

Manufacturing Specs

| Manufacturer | Spec |

|---|---|

| GM | GMW17796 |

| Stellantis | MS.90502 |